In industrial processes, accurate and reliable flow measurement ensures efficiency, safety, and cost-effectiveness. Traditional flow measurement techniques have their limitations, often requiring invasive installations and causing pressure drops or fluid contamination. However, a ground-breaking solution has emerged to overcome these challenges: the ultrasonic flow meter. In this blog, we will explore the fascinating world of ultrasonic flow meters and delve into their capabilities, advantages, and applications.

Understanding Ultrasonic Flow Meters:

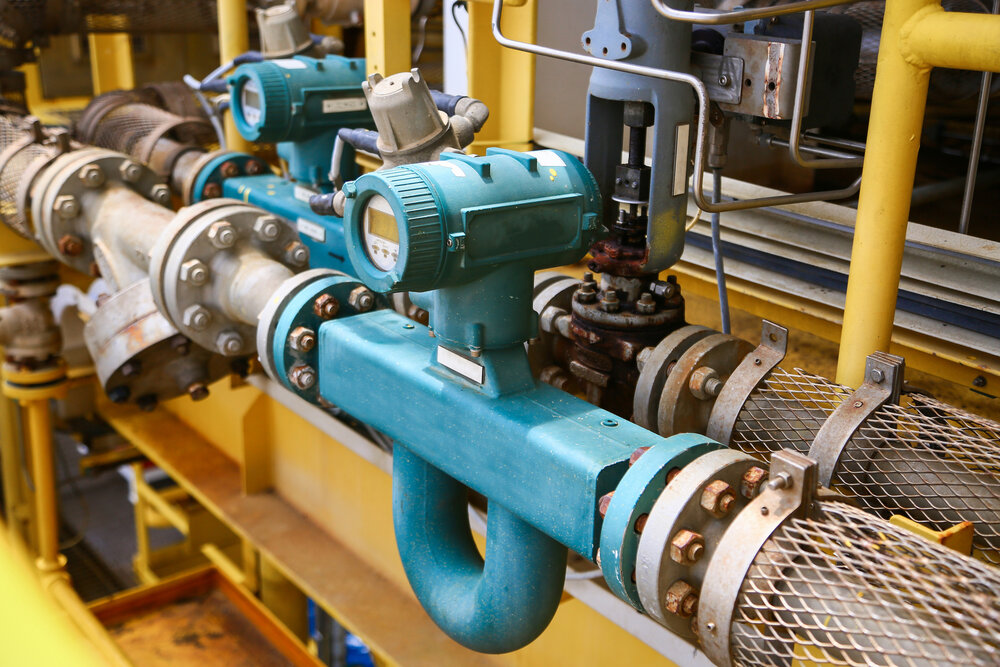

Ultrasonic flow meters utilize sound waves to measure the velocity of a flowing liquid. By transmitting ultrasonic pulses through the fluid, these devices precisely calculate the flow rate based on the time it takes for the sound waves to travel upstream and downstream. This non-intrusive technique eliminates the need for cutting pipes or interrupting the flow, making it an ideal choice for various industries.

Advantages of Ultrasonic Flow Meters:

- Non-Invasive Installation: Unlike traditional flow meters that require pipe cutting or insertion, ultrasonic flow meters can be installed externally, allowing measurements to be taken without disrupting the flow process. This advantage minimizes downtime and reduces the risk of leaks or contamination.

- High Accuracy and Reliability: Ultrasonic flow meters offer exceptional accuracy, even in challenging flow conditions. They can handle various liquid types, viscosities, and flow rates while maintaining precision. Additionally, the fluid’s electrical conductivity does not affect ultrasonic measurements, making them suitable for various applications.

- Reduced Maintenance: Ultrasonic flow meters are virtually maintenance-free with no moving parts. They do not suffer from mechanical wear and tear, reducing the need for regular repairs or replacements. This advantage leads to cost savings and increases the overall efficiency of industrial processes.

- Wide Range of Applications: Ultrasonic flow meters find applications in diverse industries such as oil and gas, chemical, water and wastewater, HVAC, and more. Their adaptability to different pipe sizes, materials, and fluid types makes them versatile for flow measurement in numerous scenarios.

- Energy Efficiency: Ultrasonic flow meters enable businesses to optimize their energy consumption by providing accurate flow measurements. They help identify and rectify inefficiencies in the flow process, leading to significant energy savings and reduced carbon footprint.

- Wide Turndown Ratio: Ultrasonic flow meters offer an excellent turndown ratio, the range of flow rates they can measure accurately. This means they can effectively measure low and high flow rates without compromising accuracy. The ability to cover a wide range of flow rates makes ultrasonic flow meters suitable for applications where flow rates vary significantly.

- Bi-Directional Flow Measurement: Unlike traditional flow meters that can only measure flow in one direction, ultrasonic flow meters can measure flow in both directions. This feature is particularly useful in applications where flow reversal can occur or in processes requiring inflow and outflow monitoring.

- Minimal Pressure Drop: Ultrasonic flow meters have a low-pressure drop across the device, ensuring that the flow characteristics of the fluid are not significantly affected. This advantage is especially important in applications where maintaining the original flow conditions and minimizing energy losses are crucial.

Conclusion:

Ultrasonic flow meters have revolutionized flow measurement by offering non-invasive installation, high accuracy, reliability, reduced maintenance, and a wide range of applications. Their ability to measure flow in both directions, minimal pressure drop, wide turndown ratio, and compatibility with different pipe sizes further enhance their benefits. As industries strive for increased efficiency, cost savings, and environmental sustainability, ultrasonic flow meters have become indispensable in optimizing flow processes and ensuring accurate measurements. By harnessing the power of sound waves, these remarkable devices have paved the way for enhanced productivity and improved resource management in various industrial sectors.

Leave a Reply